Information about current projects.

Multiscale modelling of nanomaterial synthesis

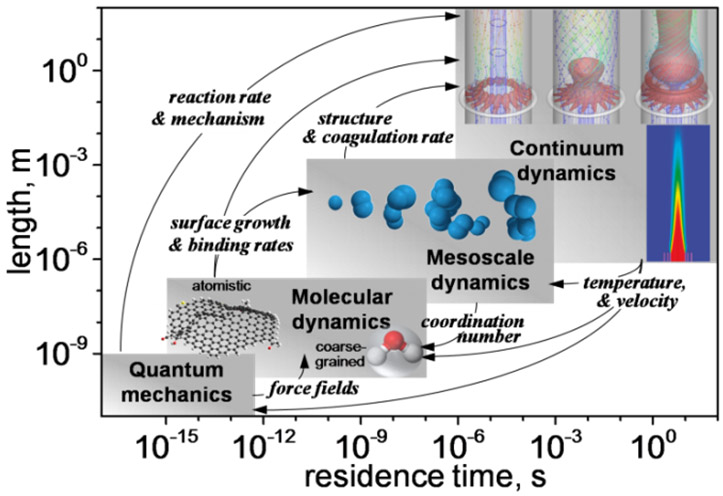

The dynamics of aerosol reactors (eg: flames) and product nanoparticle characteristics span 10 and 15 orders of magnitude in length and time. Systematic process design requires models for different length and time scales that can be distinguished into continuum, mesoscale, molecular dynamics and quantum mechanics. Efficient models are developed to explore particle formation and dynamics: Continuum models help to improve process yields and accelerate the scale-up for synthesis of new products. Mesoscale models are used to determine the evolving particle structure during coalescence from known sintering rates or obtain fractal-like particle transport and coagulation rates. Molecular dynamics models accounting for interatomic interactions give the sintering or coalescence rate of two or more particles and Reactive Molecular Dynamics bridge the gap between Molecular Dynamics and Quantum Mechanics calculations when appropriate potentials are known.

Soot kinetics from first principles

Combustion has always been one of the most important engineered chemical reactions in the world with applications in transportation, power generation or waste disposal and will remain the main source of energy for transportation for the next 50 years. However, a major technological challenge of the industry today is to design new bona fide routes to eliminate the amount of waste by-product production and energy consumption and reduce CO2 and pollutant emissions as legislated limits are steadily tightening.

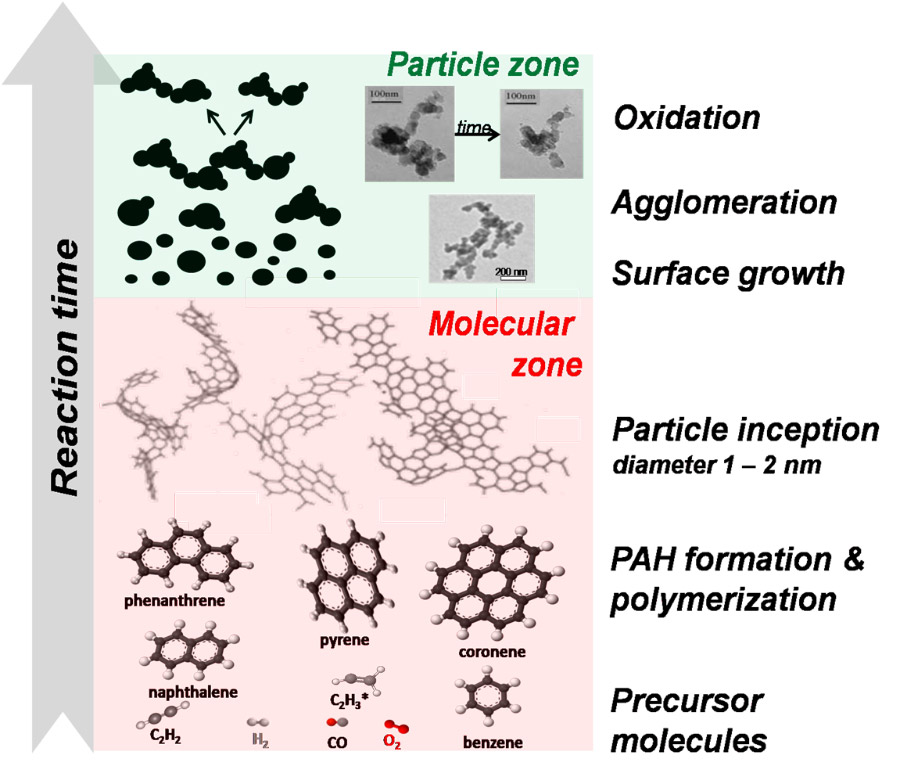

Soot, as pollutant produced in combustion, has a large impact on energy transfer in combustion systems. Accurate models that predict soot formation rate, size distribution function, its influence on combustion processes, and soot surface properties need to be developed and experimental methods need to be designed for existing and future, yet-developed combustion systems. An understanding of soot formation and soot properties at the molecular level facilitates the development of more energy-efficient, renewable and selective chemical processes, as it allows the detailed description of elementary reaction steps from reactants to products and the determination of rate constants for each individual step. Multiscale modelling can be used in the design of combustion processes in order to gain understanding of elementary gas-phase chemistry and collision dynamics of small soot precursors that lead to the formation of nascent soot nanoparticles. This will allow revisiting particle dynamics models by implementing accurate expressions for collision and binding rates obtained from the molecular level.

Design & synthesis of nanoparticles for catalytic & biomedical applications

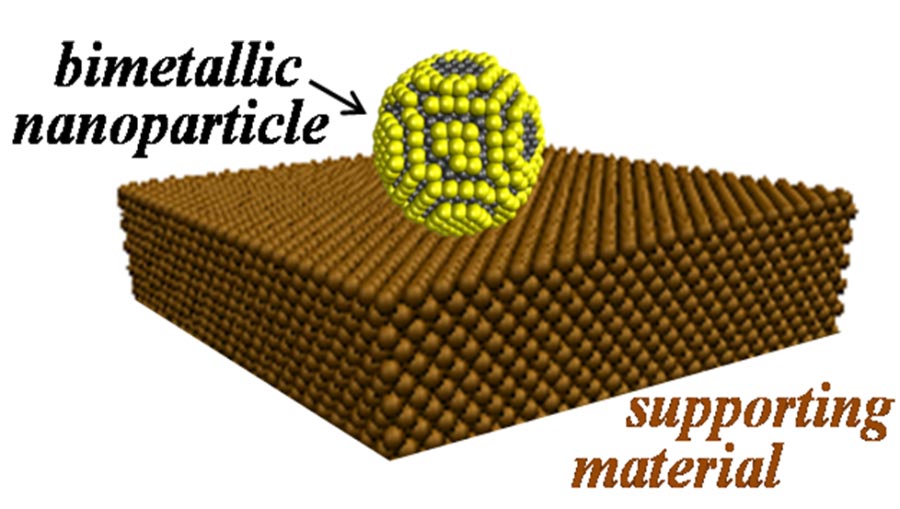

Nano-alloys exhibit unique properties compared to their pure constituent components. As a result, they have many biomedical, sensory or catalytic applications, such as ammonia decomposition and oxygenate reforming. Even slight changes in nanoparticle size, structure or composition can influence the physicochemical properties and, thus, the performance of bimetallic nanoparticles. Yet, there is only limited understanding of the structure and mixing of the two constituent metals. In fact, crystallinity is controlled rather empirically in practice.

Aerosol methods (flame spray pyrolysis) can be used for the large-scale synthesis of highly pure bimetallic nanoparticles with well-controlled particle size, morphology and composition for the identification of optimal atomic ratios that allow their use in biomedical or catalytic applications. In addition, combined quantum mechanics and MD simulations based on reactive force fields can shed light on the particles oxidation mechanism with high accuracy and low computational cost.