Near net shape forming

The use of colloidal powder processing techniques enables the fabrication of dense ceramic components with improved reliability. Complex shapes can be formed by slipcasting, gelcasting, freezecasting and 3D printing. Materials such as the oxides, borides, carbides and nitrides of Si, Al, Ti, and Zr are investigated in the group.

Ultra high temperature ceramics

We are able to process ultra-high temperature ceramics (UHTCs) that are normally difficult to densify at temperature less than via conventional means and without the application of pressure. Such materials are required for hypersonic rocket applications.

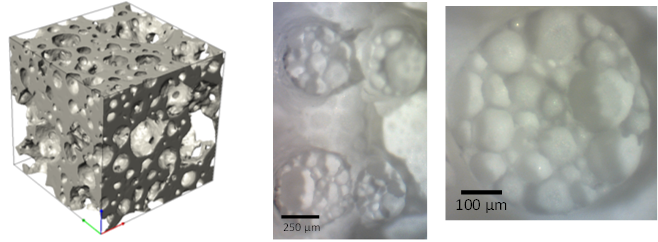

Porous ceramics

Ceramic materials with controlled porous microstructures can be produced using particle stabilised foams, ice templating, sacrificial templates, 3D printing and partial sintering. The structure can be characterised with micro computed tomography.

Suspension rheology

Improved understanding of the flow behaviour including viscosity and yield strength of suspensions underpins ceramics and minerals processing. A key outcome has been the discovery that the transition between plastic and brittle behaviour in saturated powder compacts is related to the failure of a strong touching particle sub-network. Further work into shear thickening and dilatancy of suspensions has elucidated the role of inter-particle forces in suspension flow and fracture.