Fracture of wet particulate materials and drying cracks

Improved understanding of the mechanical behaviour and fracture of wet particulate materials is crucial to understanding mud cracking common upon drying. A diametric compression technique has been developed to measure the fracture toughness of particulate materials. A recent discovery is that wet particulate materials are tougher than dry particulate materials due to plastic flow around the crack tip.

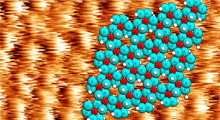

Oxide surfaces in aqueous solution

Atomic force microscopy (AFM) is used to investigate the lattice scale surface structure of oxide surfaces in aqueous solution. Density functional theory (DFT) modelling is used to understand the interaction of small shape controlling molecules with different crystal faces of ZnO.

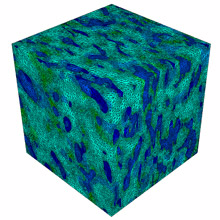

Microstructure–property modelling

The microstructure of two phase composite materials is captured with state of the art tomography techniques and manipulated into virtual 3D representation. Lattice Monte Carlo method (LMC) is used with massively parallel graphics processing units (GPUs) to predict thermal properties. Finite element analysis (FEA) is used to predict the material thermo-mechanical response to applied stress, strain and temperature gradients. The modelling is useful in predicting material performance in extreme environments not easily probed experimentally.