Microstructure

Overview

The Microstructure theme applies high resolution microscopic techniques to characterise dairy products including milk, cheese, yoghurt and dairy powders. These techniques are being used to improve our understanding of the structure of existing products and to assist Australian dairy manufacturers in the development of new products with novel properties, such as extended shelf-life or improved texture for domestic and export markets. Microstructural methods can also be used to examine the effect of changes in unit operations or the effect of equipment or process upgrades on product properties. The results of these studies can be used to develop technical guidelines for lower-cost formulations and to reduce waste by better prediction and control of undesirable processing effects during product manufacture.

Techniques such as Confocal Laser Scanning Microscopy (CLSM), cryo Scanning Electron Microscopy (cryo SEM), Atomic Force Microscopy (AFM), Transmission Electron Microscopy (TEM) and Fourier Transform Infrared (FTIR) Microspectroscopy (at the Australian Synchrotron) are used to examine samples at a laboratory, pilot and manufacturing scale. This information is then correlated with results of chemical and physical testing and other indicators of product quality.

Capabilities and technologies

Small Scale Cheese Production

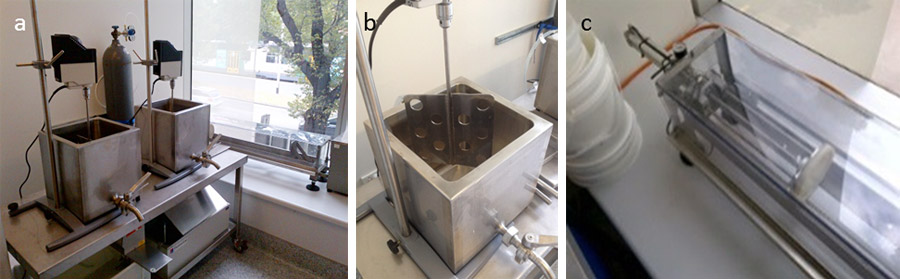

Critical to our research is the ability to produce dairy products, such as cheese and yoghurt, on a laboratory scale. This small scale plant includes two 25 L vessels (Figure 1a), each with overhead stirrers (Figure 1b) and a cheese press (Figure 1c).

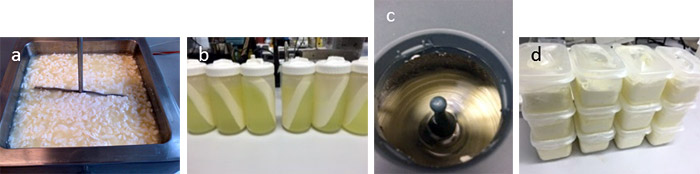

Following heating, mixing and fermentation, the curds may be cut, drained and collected to make various cheeses. Cream cheese curds undergo centrifugation, followed by heating and mixing with salt and gum in a kettle (Figure 2).

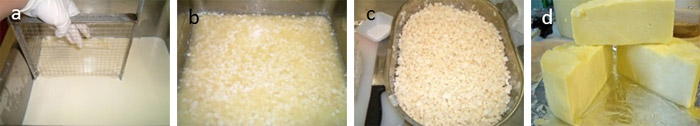

The collected curds may also be used to make semi-hard cheeses, such as pasta filata Mozzarella which involves heating and hand stretching. Alternatively, the curds may be heated and/or salted and placed in the cheese press to create harder cheeses, such as Cheddar cheese (Figure 3).

Microscopy

Microscopy is a fundamental tool in our research, which allows us to analyse, characterise and compare dairy products made commercially and in the laboratory. By altering certain ingredients or processing parameters, we can visualise at a micron scale, the changes made to the product during the production process.

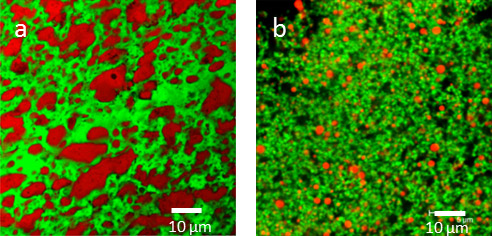

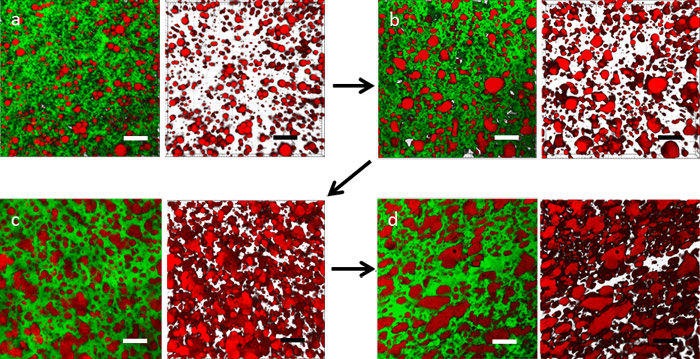

CLSM is an essential technique used to characterise the microstructure of dairy products (Figure 4). CLSM has been used to visualise and chemically differentiate dairy components through the use of protein and lipid specific stains. The optical sectioning capabilities allow samples to be observed at high resolution with minimal sample preparation. The laser beam penetrates through the bulk of a sample and structural information can be obtained at different depths.

By obtaining sets of images at different depths of the dairy sample, we are able to reconstruct a three-dimensional image (Figure 5), which with image analysis software, can provide quantitative information. Parameters such as total volume of protein or fat, total porosity and mean fat sphericity and diameter are obtained and linked to the functional properties of the product.

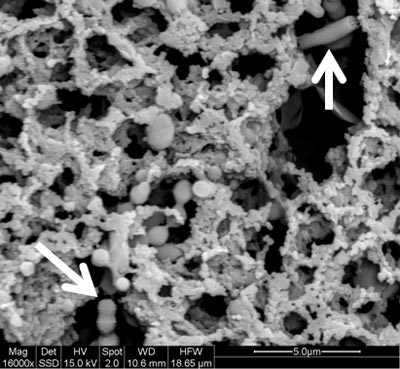

Cryo SEM is also an important technique that can be used to provide a highly detailed surface microstructure of dairy products. Cryogenic sample preparation preserves the fine microstructure of highly hydrated samples, such as yoghurt, rennet gels (Figure 6) and cheese. It allows hydrated samples to be examined without the chemical staining and dehydration steps that are often involved in conventional SEM observation.

Other microscopy techniques applied by the team include AFM, cryo TEM, light microscopy and FTIR microspectroscopy.

Characterisation of cheese texture and functionality

In addition to microscopic analysis, dairy products are subjected to texture and functionality tests. These results are compared with those obtained from microscopy and structure-function relationships are established. Instruments that measure texture (Figure 7) include:

- A viscometer: provides on-site measurement of the viscosity of a sample during processing, (cream cheese and yoghurt production).

- A rheometer: allows the flow properties to be measured, in addition to melting properties, such as transition temperatures, (cream cheese, Mozzarella cheese and Cheddar cheese).

- A texture analyser: provides information relating to a sample’s hardness, spreadability, adhesiveness or other textural properties, (cream cheese, Mozzarella cheese and Cheddar cheese).

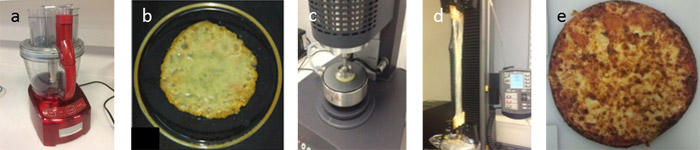

Procedures that measure functionality (Figure 8) include:

- Shreddability

- Meltability

- Stretchability

- Pizza bake test

Analytical capabilities

Other techniques used for the characterisation of various dairy products include high performance liquid chromatography (HPLC), ultra performance liquid chromatography (UPLC), liquid chromatography-mass spectrometry (LC-MS), gas chromatography-mass spectrometry (GC-MS), nuclear magnetic resonance (NMR) spectroscopy, SDS-PAGE to determine protein profiles, particle size analysis (Mastersizer), compositional analysis including fat analysis (Babcock and Mojonnier), salt analysis (Volhard) and protein analysis (LECO elemental analyzer).

The research group also has access to a broad range of platform technologies (proteomics, metabolomics, NMR, microscopy) as part of the Bio21 Molecular Science and Biotechnology Institute.

Outcomes

- The microstructure team has helped Australian dairy manufacturers to bench mark the microstructure and properties of commercial cheese and yoghurt products.

- The team has set up a small scale cheese (25 L) and yoghurt making (4 L) facility at the Bio21 Institute. This facility allows the effects of processing variables and techniques to be assessed at much lower cost and risk, assisting quality control and consistency.

- Capabilities have been developed including microstructural, image analysis, textural, rheological and proteomic characterisation methods that can be applied to a variety of dairy products including milk, cheese, butter, yoghurt and dairy powders.

- The team is currently examining the effects of process variables in cream cheese and Mozzarella cheese making. The results from these studies will allow manufacturers to measure the impact of process operations on product properties and correlate microstructure with functional properties, assisting in process control and the improvement of product quality and consistency.

- The team has also applied their capabilities in a commercial setting through a series of case studies and has completed several contracts that have assisted dairy manufacturers in three main areas: (1) bench marking of existing products and validation of product quality after processing changes or upgrades, (2) assessment of product quality control prior to release for export, lowering the risk of export trade and enabling entry to new markets and (3) diagnostic analysis of products, reverse engineering and product development.

Publications

2020

Ong, L., Pax, A., Ong, A., Vongsvivut, J., Tobin, M., Kentish, S. E. & Gras, S. L. (2020) The effect of pH on the fat and protein within cream cheese and their influence on textural and rheological properties, Food Chemistry, https://doi.org/10.1016/j.foodchem.2020.127327 (In press).

Daffner, K., Hanssen, E., Norton, I., Mills, T., Ong, L. & Gras, S. (2020) Imaging of dairy nanoemulsions via a novel approach of transmission electron cryogenic microscopy using beam exposure, Soft Matter, https://doi.org/10.1039/x0xx00000x (In press).

Devnani, B., Ong, L., Kentish, S. E. & Gras, S. L. (2020) Heat induced denaturation, aggregation and gelation of almond proteins in skim and full fat almond milk, Food Chemistry, https://doi.org/10.1016/j.foodchem.2020.126901.

Daffner, K., Vadodaria, S., Ong, L., Nöbel, S., Gras, S. L., Norton, I. & Mills, T. (2020) Design and characterization of casein-whey protein suspensions via the pH-temperature-route for application in extrusion-based 3D-Printing, Food Hydrocolloids, https://doi.org/10.1016/ j.foodhyd.2020.105850.

Lazzaro, F., Bouchoux, A., Raynes, J., Williams, R., Ong, L., Hanssen, E., Lechevalier, V., Pezennec, S., Cho, H.-J., Logan, A., Gras, S. L. & Gaucheron, F. (2020) Tailoring the structure of casein micelles through a multifactorial approach to manipulate rennet coagulation properties, Food Hydrocolloids, 101, 105414.

2019

Ong, L., D’Incecco, P., Pellegrino, L., Nguyen, H. T. H., Kentish, S. E. & Gras, S. L. (2019) The effect of salt on the structure of individual fat globules and the microstructure of dry salted Cheddar cheese. Food Biophysics https://doi.org/10.1007/s11483-019-09606-x.

Aldalur, A., Ong, L., Bustamante, M. A., Gras, S. L. & Barron L. J. R. (2019) Impact of processing conditions on microstructure, texture and chemical properties of cheese from sheep milk. Food and Bioproducts Processing, 116, 160–169.

Pax, A., Ong, L., Vongsvivut, J., Tobin, M. J., Kentish, S. E. & Gras, S. L. (2019) The characterization of Mozzarella cheese microstructure using high resolution synchrotron transmission and ATR-FTIR microspectroscopy. Food Chemistry, 291, 214–222.

Macdougall, P. E., Ong, L., Palmer, M. V. & Gras, S. L. (2019) The microstructure and textural properties of Australian cream cheese with differing composition. International Dairy Journal, 99, 104548.

2018

Ong, L., Kentish, S. E. & Gras S. L. (2018) Small scale production of cream cheese: A comparison of batch centrifugation and cloth bag methods. International Dairy Journal, 81, 42-52.

D’Incecco, P., Ong, L., Gras, S. L. & Pellegrino, L. (2018) A fluorescence in situ staining method for investigating spores and vegetative cells of Clostridia by confocal laser scanning microscopy and structured illuminated microscopy. Micron, 110, 1–9.

D’Incecco, P., Ong, L., Pellegrino, L., Faoro, F., Barbiroli, A. & Gras, S. L. (2018) Effect of temperature on the microstructure of fat globules and the immunoglobulin-mediated interactions between fat and bacteria in natural raw milk creaming. Journal of Dairy Science, 101, 2984–2997.

2017

Nguyen, H. T. H., Ong, L., Lopez, C., Kentish, S. E. & Gras, S. L. (2017) Microstructure and physicochemical properties reveal differences between high moisture buffalo and bovine Mozzarella cheeses. Food Research International, 102, 458–467.

Ong, L., Powell, I. B., Lawrence, R. C., Gilles, J., Creamer, L. K., Crow, V. L., Heap, H. A., Honoré, C. G., Johnston, K. A., Samal, P. K. & Gras, S. L. (2017) Chapter 33 – Cheddar cheese and related dry-salted cheese varieties. In: McSweeney, P. L. H., Fox, P. F., Cotter, P. D. & Everett, D. (Eds.), Cheese: Chemistry, Physics and Microbiology (4th edition, volume 2, pp. 829-863), Academic Press.

Soodam, K., Ong, L., Powell, I. B., Kentish, S. E. & Gras, S. L. (2017) Effect of elevated temperature on the microstructure of full fat Cheddar cheese during ripening. Food Structure, 14, 8–16.

Nguyen, H. T. H., Ong, L., Hoque, A., Kentish, S. E., Williamson, N. & Ang, C. S. (2017) A proteomic characterization shows differences in the milk fat globule membrane of buffalo and bovine milk. Food Bioscience, 19,7–16.

2016

Nguyen, H. T. H., Madec, M.-N., Ong, L., Kentish, S. E., Gras, S. L. & Lopez, C. (2016) The dynamics of the biological membrane surrounding the buffalo milk fat globule investigated as a function of temperature. Food Chemistry, 204, 343–351.

Chandrapala, J., Ong, L., Zisu, B., Gras, S. L., Kentish, S. E. & Ashokkumar, M. (2016) The effect of sonication and high pressure homogenization on the properties of pure cream. Innovative Food Science & Emerging Technologies, 33, 297–307.

2015

Soodam, K., Ong, L., Powell, I.B., Kentish, S. E. & Gras, S. L. (2015) Effect of rennet on the composition, proteolysis and microstructure of reduced-fat Cheddar cheese during ripening. Dairy Science and Technology, 95(5), 665–686.

Soodam, K., Ong, L., Powell, I. B., Kentish, S. E. & Gras, S. L. (2015) Effect of calcium chloride addition and draining pH on the microstructure and texture of full fat Cheddar cheese during ripening. Food Chemistry, 181, 111–118.

Ong, L., Soodam, K., Kentish, S. E., Powell, I. B. & Gras, S. L. (2015) The addition of calcium chloride in combination with a lower draining pH to change the microstructure and improve fat retention in Cheddar cheese. International Dairy Journal, 46, 53–62.

Nguyen, H. T. H., Ong, L., Kentish, S. E. & Gras, S. L. (2015) Homogenisation improves the microstructure, syneresis and rheological properties of buffalo yoghurt. International Dairy Journal, 46, 78–87.

Nguyen, H. T. H., Ong, L., Kentish, S. E., Gras, S. L. & Lopez, C. (2015) Buffalo milk fat globules and their biological membrane: in situ structural investigations. Food Research International, 67, 35–43.

2014

Soodam, K., Ong, L., Kentish, S. E., Powell, I. B. & Gras, S. L. (2014) The effect of milk protein concentration on the microstructure and textural properties of full fat Cheddar cheese during ripening. Food and Bioprocess Technology, 7, 2912–2922.

Nguyen, H. T. H., Ong, L., Kentish, S. E. & Gras, S. L. (2014) The effect of fermentation temperature on the physiochemical, rheological properties and microstructure of buffalo yoghurt. Food and Bioprocess Technology, 7, 2538–2548.

Nguyen, H. T. H., Ong, L., Kentish, S. E. & Gras, S. L. (2014) The microstructure and physicochemical properties of probiotic buffalo yoghurt during fermentation and storage: A comparison with bovine yoghurt. Food and Bioprocess Technology, 7, 937–953.