Milk streams

Overview

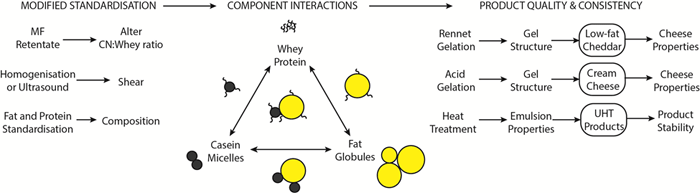

The development of milk streams with novel functionalised properties is of high interest to the dairy industry as a means to add significant value to existing processes and product lines. This project aims to develop and apply upstream process inventions, such as microfiltration, double emulsions, ultrasound and homogenisation to control the interactions of casein micelles, whey proteins and fat globules to improve the yield, quality and consistency of low-fat Cheddar and cream cheese products and the stability and shelf-life of UHT dairy beverages (Figure 1). This project is focused on understanding the interplay and implications between dairy fats and proteins within these novel dairy products that have been developed using these technologies.

Capabilities and technologies

Microfiltration

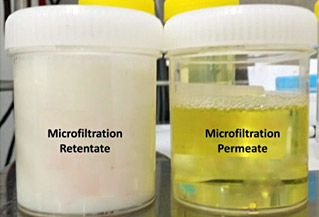

Microfiltration technology has allowed us to create novel protein ingredient streams that can be used to make new products. The membranes enable the splitting of whey proteins directly from casein in skim milk, producing a whey stream (microfiltration retentate) that is pure, sterile and unadulterated (Figure 3). Microfiltration retentates possess superior quality and functionality to the normal whey proteins obtained from conventional cheese making.

Ultrasound and homogenisation

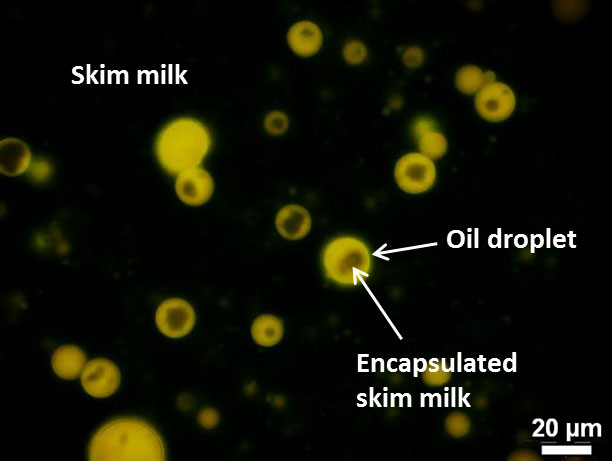

A novel method has been developed using ultrasound to create double emulsions with minimal addition of stabilisers (Figure 4). The stability of dispersed fat droplets is inferred primarily by casein and whey proteins present in the milk matrix. These emulsions can be directly transformed into cheese products.

Ultrasound and homogenisation have also been used to: (1) modify the properties of fat droplets, (2) alter temperature-induced reactions during UHT treatment by prior or simultaneous application and (3) modify fat-whey-casein interactions.

Outcomes

- Our project is currently assessing the utilisation of enriched casein streams to enhance the process kinetics of cheese and other potential benefits in the production of cream cheese, low fat Cheddar and UHT products.

- Double emulsion technology has enabled us to encapsulate an aqueous phase within the fat droplets of skim milk. This process can be used to displace fat (low fat products), replace fat (using fat alternatives in cheese) or microencapsulate water soluble flavours or nutrients within the fat droplets of processed cheese (Figure 5) or UHT products.

The project is also expected to:

- Improve product consistency and optimise yields in cream cheese manufacture.

- Produce low fat Cheddar cheese with good flavour and texture.

- Address low stability of UHT products during storage.

Publications

2020

Leong, T. S. H., Ong, L., Gamlath, C. J., Gras, S. L., Ashokkumar, M. & Martin, G. J. O. (2020) Formation of Cheddar cheese analogues using canola oil and ultrasonication - A comparison between single and double emulsion systems. International Dairy Journal, https://doi.org/10.1016/j.idairyj.2020.104683.

Pathak, R., Leong, T. S. H., Martin, G. J. O. & Ashokkumar, M. (2020) Amino acid and secondary structure integrity of sonicated milk proteins. Australian Journal of Chemistry, https://doi.org/10.1071/CH19372.

Li, W., Gamlath, C. J., Pathak, R., Martin, G. J. O. & Ashokkumar, M. (2020) Book chapter – Ultrasound – The physical and chemical effects integral to food processing. In: Reference Module in Food Science, Elsevier, https://doi.org/10.1016/B978-0-08-100596-5.22679-6.

2019

Chen, G. Q., Leong, T. S. H., Kentish, S. E., Ashokkumar, M. & Martin, G. J. O. (2019) Chapter 8 – Membrane separations in the dairy industry. In: Galanakis, C. M. (Ed.) Separation of Functional Molecules in Food by Membrane Technology, (pp. 267–304), Academic Press, https://doi.org/10.1016/B978-0-12-815056-6.00008-5.

Munir, M., Nadeem, M., Qureshi, T. M.., Leong, T. S. H., Gamlath, C. J., Martin, G. J. O. & Ashokkumar, M. (2019) Effects of high pressure, microwave and ultrasound processing on proteins and enzyme activity in dairy systems – A review. Innovative Food Science and Technology, https://doi.org/10.1016/j.ifset.2019.102192.

2018

Leong, T. S. H., Martin, G. J. O. & Ashokkumar, M. (2018) Chapter 8 - Ultrasonic food processing, In: Proctor, A. (Ed.) Alternatives to Conventional Food Processing (2nd Edition, pp. 316–354), RSC Publishing.

Leong, T. S. H., Manickam, S., Martin, G. J. O., Li, W. & Ashokkumar, M. (2018) Ultrasonic production of nano-emulsions for bioactive delivery in drug and food applications, SpringerBriefs in Molecular Science, Springer, https://doi.org/10.1007/978-3-319-73491-0.

Leong, T. S. H., Zhou, M., Zhou, D., Ashokkumar, M. & Martin, G. J. O. (2018) The formation of double emulsions in skim milk using minimal food-grade emulsifiers - A comparison between ultrasonic and high pressure homogenisation efficiencies. Journal of Food Engineering, 219, 81–92.

Li, W., Leong, T. S. H., Ashokkumar, M. & Martin, G. J. O. (2018) A study of the effectiveness and energy efficiency of ultrasonic emulsification. Physical Chemistry Chemical Physics, 20, 86–96.

Gamlath, C. J., Leong, T. S.H., Ashokkumar, M. & Martin, G. J. O. (2018) The inhibitory roles of native whey proteins on the rennet gelation of bovine milk. Food Chemistry, 244, 36–43.

Leong, T. S. H., Walter, V., Gamlath, C. J., Yang, M., Martin, G. J. O. & Ashokkumar, M. (2018) Functionalized dairy streams: Tailoring protein functionality using sonication and heating. Ultrasonics Sonochemistry, 48, 499–508.

2017

Leong, T. S. H., Martin, G. J. O. & Ashokkumar, M. (2017) Ultrasonic encapsulation - A review. Ultrasonics Sonochemistry, 35(part B), 605–614.

Leong, T. S. H., Ashokkumar, M. & and Martin, G. J. O. (2017) Preparation of water-in-oil-in-water emulsions by low frequency ultrasound using skim milk and sunflower oil. Food Hydrocolloids, 63, 685–695.